The quality of insulated profiles depends on the materials used. The production method also affects the end result quality and costs. The conventional product process consists of three steps.

High-quality insulated aluminium profiles in just 3 steps

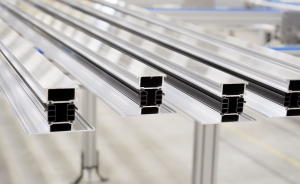

The production of aluminium window profiles with a thermal break does not require anything very complicated: just two aluminium extrusions with an insulating strip in between. These strips can be made using materials like Polyamide, ABS, PVC or Noryl. The insulating strips are absolutely necessary to break the thermal bridge, since aluminium is a poor insulator on its own.

Once the profile is insulated, the energy performance improves dramatically. The materials are the easy part, however; achieving excellent quality requires a high-end thermal break assembly process. There are three steps to assembling effectively insulated aluminium profiles:

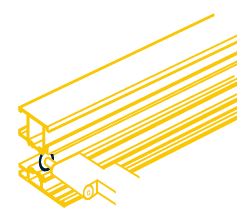

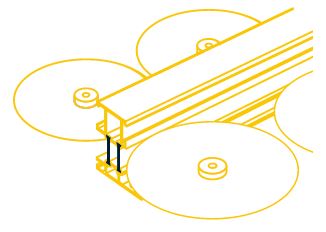

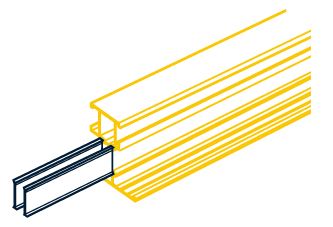

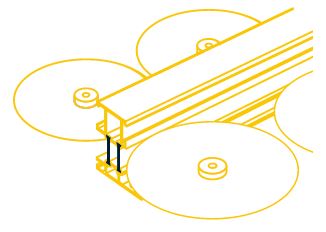

- Knurling: hardened knurling wheels are used to leave ridged impressions in the cavity inside the aluminium extrusions. These ‘teeth’ will keep the insulating strips in place once the third step of the assembly process has taken place (crimping, see below).

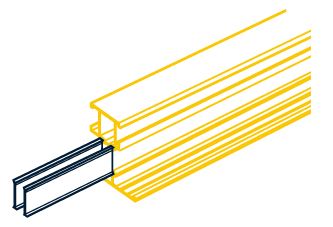

- Strip insertion: the insulating strip is inserted into the cavity between the aluminium extrusions. This is precision work; the strip must be inserted precisely between the 'teeth’ (the ridged impressions created in step 1).

- Crimping: this is the most important step in the process, and will determine the ultimate quality of the profile. The 'teeth’ of the top and bottom aluminium extrusion are folded to keep the insulating strip in place. This ensures that the insulating strip forms a layer between the inside and outside of the aluminium profile. This thermal break ensures that the interior temperature remains pleasant during freezing winters and sweltering summers.

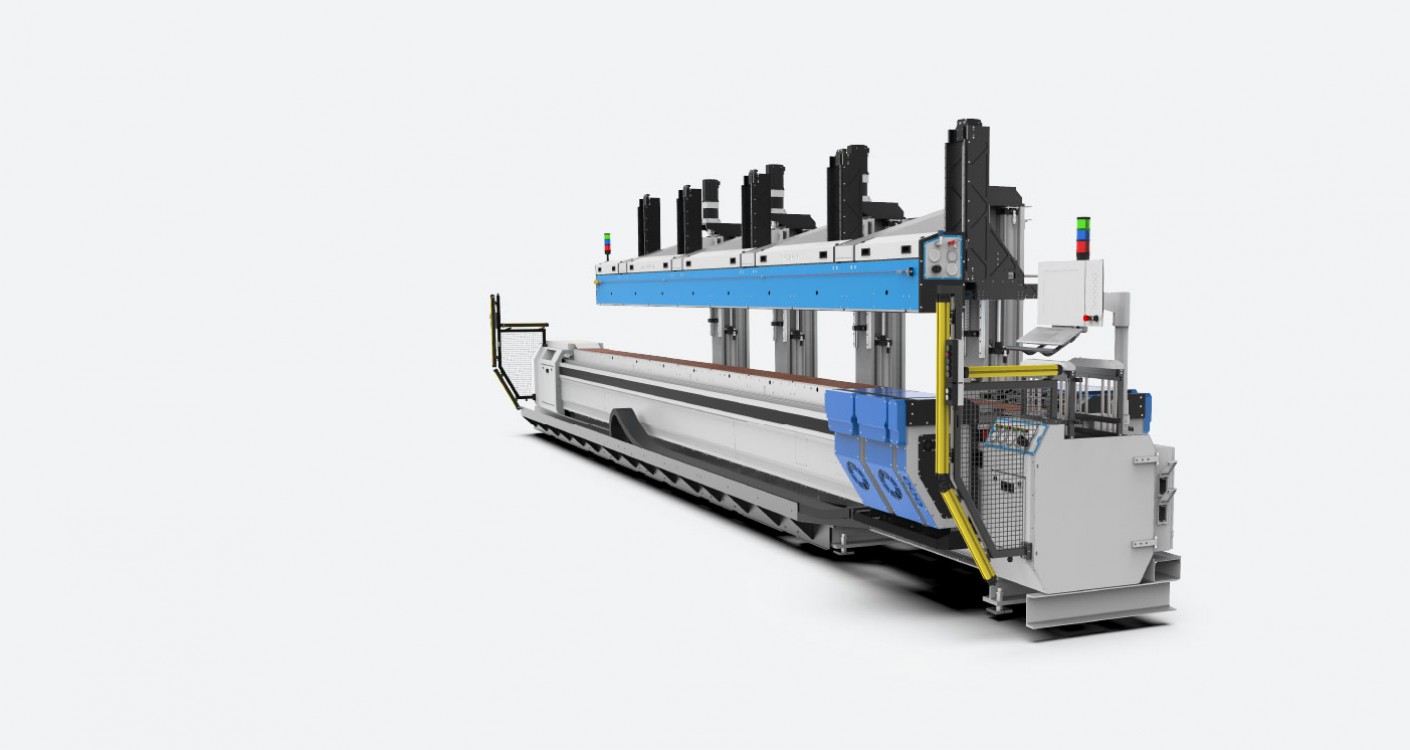

Aluro is a pioneer in its field, and one of the global market leaders in machines used to manufacture thermally broken aluminium profiles. Almost 30 years ago, Aluro developed the Aluroller, their unique 3-in-1 thermal break machine.

3-in-1 solution

In line with its commitment to innovation, Aluro developed a 3-in-1 solution: one single machine that handles all three steps of the production process. This first resulted in the Aluroller, followed in 2015 by the Aluroller EVO. It takes up less space than three separate machines, allows for faster changes (only 1 set-up needed), requires fewer operators, and also provides top-quality window profiles. Thanks to all these advantages, the Aluroller EVO is the perfect solution for companies that not only produce large batches, but also handle smaller orders for a variety of profiles.

Leave a comment