Everybody is convinced that thermal break window profiles are important. However, not all profiles are the same. Thanks to its state-of-the-art range of machines and quality services, Aluro is now the market leader in machinery used to manufacture thermal break window profiles.

Superior technology and a comprehensive service package

Aluro leads the market for thermal break window profiles

Aluro was founded in Heist-op-den-Berg, Belgium in 1969, originally starting out as a family business. Almost 50 years later, it has grown into a benchmark in the world of machinery for the manufacturing of thermal break window profiles. The first steps towards expansion into France were taken in the 1990s. Aluro's reach has grown since then. The company now works with partners in Ireland, Spain, Greece, the United Kingdom, Poland, Italy, Portugal and Turkey, as well as farther away in the United States, Australia and New Zealand. International success demands the expansion of the company. In 2016, Aluro’s US offices opened in Atlanta, Georgia.

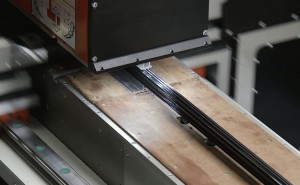

What makes Aluro so special? It is the only company in the world totally dedicated to machinery used to manufacture thermal break window profiles. Manufacturing thermal break window profiles requires 3 operations: knurling, strip insertion (e.g. polyamide, ABS, PVC or Noryl), and crimping. Aluro has a prime machine in its BTM range for each process.

Revolution: 3-in-1 solution

A revolution in manufacturing took place in 1985. After years of investments in research & development, Aluro began supplying the first Aluroller, a 3-in-1 solution which covers all 3 required operations. While 3 independent machines were previously needed with at least 3 to 5 operators, 2 operators now suffice. A single machine also occupies less space than 3. Programming the Aluroller is as simple as it is precise, and changeover times are minimised to maximise the machine’s efficiency. This also allows for quicker production of different series without any delays, resulting in shorter delivery times. Thanks to the precise alignment and correct finishing, production defects such as deformed or non-perfect straight profiles no longer occur, and waste production is minimised.

The second generation

After 30 years of research and improvements to the first Aluroller, the second generation was launched: the Aluroller EVO. The most noticeable improvements are the Lift-Assist (Articulated Lifting Arm) and the renewed carriage. This new carriage is equipped with a knurling rotation system, 4 pairs of individually adjustable rollers, and an optional automatic strip guide. The EVO has been fitted with everything to make the production process even more efficient.

Comprehensive services

Aluro has developed a complete service package for this superior technology. It is clear that the company continuously invests in product improvement. Aluro's specialists work together with customers to find further opportunities for potential process improvements. Once the ideal configuration has been chosen, these specialists take care of the installation and advise customers during the commissioning process. They also provide training on the use of the machine on request and continue to provide (often remote) technical assistance and maintenance.

No other market party offers this combination of exceptional technology and excellent service. Anyone looking for the best possible quality knows exactly who they can trust.

- Peter De Roovere

Leave a comment