- Maintenance of your Thermal Break Machines and Outfit

- Relocation of your Thermal Break installations

- Intervention to repair defects

- Replacement of broken machine parts

Maintenance of your Thermal Break Machines and Outfit

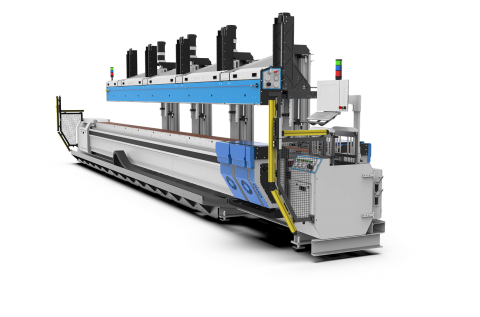

In order to avoid stagnation of your productivity, it is important to keep your machines in top shape. That is why we can offer you both preventive maintenance of your equipment as well as advice on replacement parts. During maintenance, we'll not only look after the mechanical functioning of your machines and outfit, but also revise the electronics and software.

Relocation of Thermal Break installations

Also for the relocation of your Thermal Break Machines and Outfit, Aluro is at your service. We have installed our machines and outfit all over the world, and know exactly what needs to be taken into account when dismantling your machines for a relocation. Also for the transportation and re-installation and start-up, we have all the needed skills and know-how on how to make this happen. Effectively and at low cost.

Interventions & Replacements

Thanks to the CNC-steering mechanism of our Aluroller EVO, we can make interventions remotely when possible. But we'll travel to your premises when needed. Our service engineers have both the mechanical, electronical and software expertise to fix your problems on site. If spare parts are in order, we'll make sure these are delivered and installed at the speed of light!

Reynaers Aluminium is one of Aluro's 'oldest' customers. They were...

read more