The market of window isolation is rapidly changing. Not only are end consumers demanding better isolation (e.g. passive building). Governments are also imposing higher isolation standards. As market leader in the thermal break assembly for aluminium profiles, Aluro has anticipated this drastic market evolution.

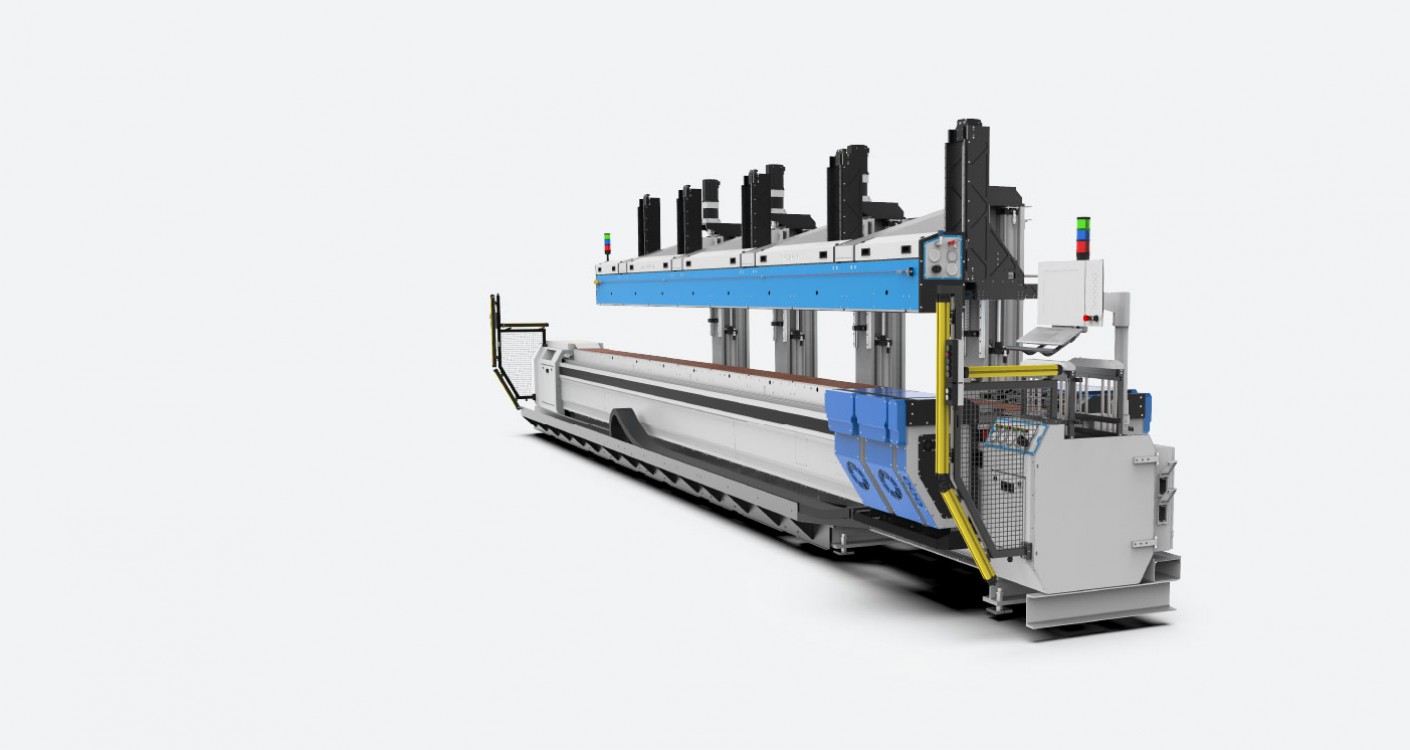

Thanks to the extensive experience which Aluro has gained over the past 25 years, Aluro is able to offer superior technology to boost your thermal break assembly. Our Aluroller EVO, the most efficient machine for thermal break assembly in the industry, allows you to knurl, to insert isolation strips and to roll to assemble aluminium profiles for windows and curtain walls.