- Benefit from 25 years of experience in Thermal Break Assembly

- Improve your know-how as well as the efficiency of your organization

- Strive for better quality of your end products

- Increase the productivity of your business

Benefit from 25 years of experience in Thermal Break Assembly

With over 25 years of experience, know-how and relations with both our customers and suppliers of isolation technologies, we have gathered a wealth of knowledge. You can benefit from that: we’ll be glad to share our knowledge with you to further improve the efficiency of your organization.

Improve your know-how as well as the efficiency of your organization

With customers in over 25 countries, we are proud to call ourselves an expert in Thermal Break Assembly. We'll let you in on the BDP's for Thermal Break Assembly, which will allow you to improve the efficiency of your organization.

Strive for better quality of your end products

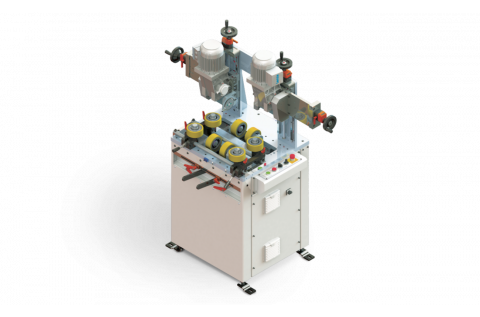

As a European manufacturer of machines for Thermal Break Assembly, you can benefit from our proximity to state-of-the art technology of window profiles and isolation techniques. Although we cannot share the technology of our customers, we can help you to obtain a better quality of your end products.

Increase the productivity of your business

As an expert in Thermal Break Assembly and as a provider of Machines, Outfit ánd Service, we'll be able to guide you towards a significantly higher productivity of your business. How exactly? Get in touch with us today, and we'll be glad to tell you more about it!

The fast set-up times and extreme high efficiency allow for fast production times and easy switch-over between batches. You can quickly shift from one profile type to the next.