Witness the Aluroller EVO at GlassBuild Atlanta!

We invite you to an exciting showcase at this year's GlassBuild exhibition in Atlanta, from October 31st to November 2nd.

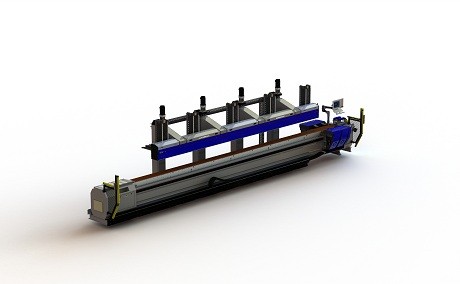

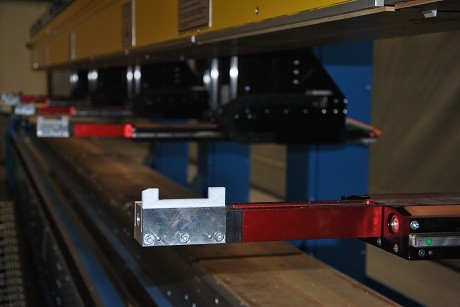

For the first during a public event in the United States, we will be presenting the Aluroller EVO — embodying the pinnacle of thermal break assembly technology. Here's a snapshot of its distinct advantages: