Double or even triple glazing provides a good basis for the thermal insulation of your windows. However, you shouldn’t overlook the window profiles. In order to avoid heat loss this way, you can better choose thermal break profiles. They contain a plastic thermal barrier. ABS is one of these and in this area forms a worthy alternative to polyamide, PVC and Noryl, for example.

ABS additional advantage with window insulation

When reading or hearing the letter combination ABS, you most probably first think of your car's anti-lock braking system. However, this abbreviation refers to a polymer, a sort of plastic, which you’ll undoubtedly find in your home. Screen housings and other household appliances – for example your vacuum cleaner or your mixer are made of this, or your car bumper, or your children’s LEGO bricks. And if you’re older than thirty, without a doubt you’ll know the Rubik’s cube – also made of ABS. You see - the chances that you’ve never come across ABS are pretty small, even though you weren’t always aware of it.

Thermal barrier

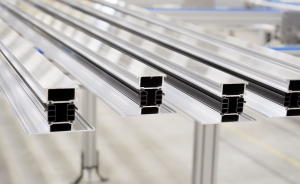

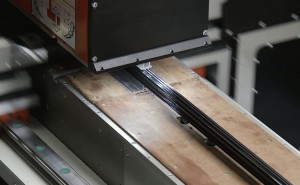

ABS however is used in the production of thermal break window profiles as an alternative for other polymers including polyamide, PVC or Noryl. Strips of these polymers are placed between two aluminium extrusions during the production process. This way they form a thermal barrier, which ensures that you keep heat inside more easily in the winter, while in summer, the heat remains outside.

In itself, aluminium is highly suited as a material for the manufacture of window profiles. In comparison with wood for example, the only downside is the limited thermal insulation. Simply put: even with double or triple glazing, you suffer significant heat loss in winter with basic aluminium profiles. That shortcoming is eliminated through the addition of the aforementioned strips, which can be manufactured from ABS.

Right mix of 3 components

ABS is the abbreviation of Acrylonitrile-Butadiene-Styrene. All three of these components provide a contribution to the specific characteristics of this polymer. Acrylonitrile provides chemical resistance, hardness, rigidity and resistance to ageing. Butadiene provides low flexibility under the influence of temperature and high melt strength. Finally, styrene contributes to ease of processing, gloss, and also to hardness.

When the three components are combined in the correct ratio (typically 50% styrene, 5 to 30% butadiene and the remainder acrylonitrile), you obtain a plastic that is highly suitable for creating a thermal barrier in window profiles. ABS is light, requires no maintenance, is dimensionally stable and, most importantly in this case, has excellent insulation properties, both acoustic and thermal. In this way ABS significantly contributes to a pleasant temperature throughout your home all year round.

- Peter De Roovere

Leave a comment